Dairy barn construction costs and impacts

- September 22, 2023

Building a new barn is a major investment with a significant impact on animal comfort and productivity as well as long-term farm profitability. Much has been said in recent years about the comfort of animals, but there have also been repeated reports of cost overruns in construction projects leading to precarious financial situations. In light of this context, Lactanet carried out a project to gather available information on some sixty recent barn construction projects (2017-2022) to gain a better understanding of the issues and challenges at the heart of these investment decisions.

The survey included approximately sixty buildings spread geographically across Quebec that covered the various milking systems, the different herd sizes, cold barns, heifer and dry cow barns, and nurseries. Each building was surveyed to gather detailed information on the building, its equipment, the construction project process, construction costs, and animal welfare and productivity. The results of the survey enabled us to establish associations for construction costs as well as the impact on animal productivity and welfare. Here are preliminary results from about thirty insulated dairy barns.

1. Construction costs

To reflect the 2023 costs, the construction costs for each project were adjusted for inflation over the 2017-2022 period. In addition, the costs for the purchase of cows, quota and items outside the buildings (e.g., pits, warehouses, silos) were excluded.

Table 1 shows average costs based on various parameters as well as the 20th and 80th percentiles. Although costs were adjusted for inflation, there are great disparities in our sample—costs can vary by about 20% above or below the average. In our analyses, we found two main reasons that could explain most of these differences:

- The level of automation in barns is an important factor. Some projects had a very high level of automation for milking, feeding, and bedding and manure management. These initial investments should be offset by production gains and/or savings in variable expenses. Other projects included only a few of these types of equipment.

- Cost overruns and project management and planning are also important considerations. On the one hand, some farmers were successful in managing their project, planning the work and negotiating with the various contractors and suppliers. On the other hand, some had to deal with delays, contractor or supplier changes, or modifications to the project itself. These differences underline the importance of planning and good project management.

Table 1: Construction costs (2023) – insulated dairy barns (n = 29)

Construction costs (dairy barns) | Median | P20a | P80b |

Cost per square foot ($/ft2) | 101 | 81 | 112 |

| Cost per head ($/head) | 18,160 | 14,920 | 20,890 |

Cost per kg of quotac ($/kg) | 23,000 | 18,300 | 27,280 |

| Cost of equipment ($/cow) | 7,100 | 5,830 | 8,910 |

| Cost of the building only ($/ft2) | 60.1 | 51.4 | 65.2 |

a Corresponds to the 20th percentile.

b Corresponds to the 80th percentile.

c Quota produced when the animals arrived in the new building.

2. Impact on production

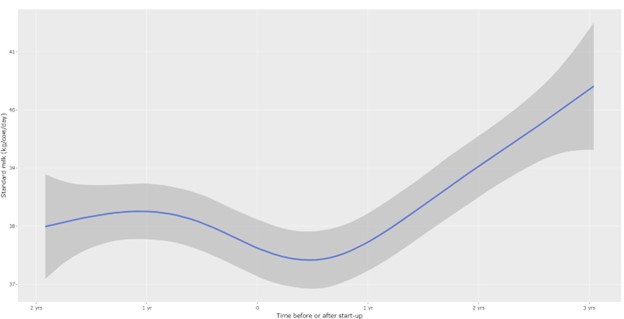

We noted that herd production was directly impacted by the new barn and, in many cases, this impact was felt even before the start-up date (see Figure 1). On average, the production of the herds analyzed declined in the first year and then came back up in the second and third years of operation. This could be due to:

- The stress caused by construction and the lack of time impacting herd management.

- The adaptation of management strategies to a new environment (e.g., bedding and humidity management, and adaptation to the robot)

Average production growth is estimated at just over 1.5 kg/cow/day in the second year, and at 1 kg/cow/day in the third.

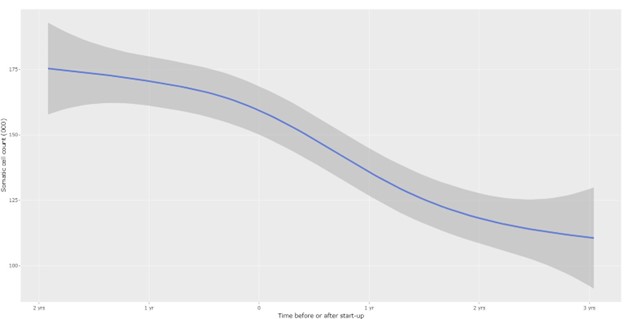

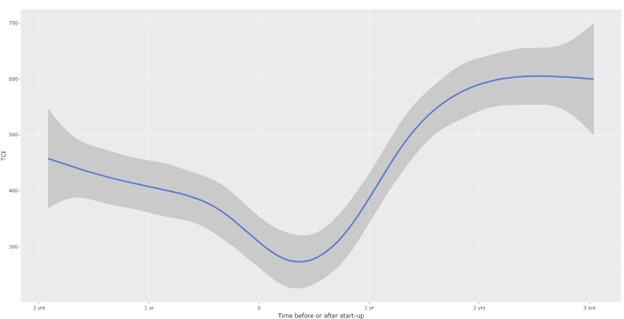

Finally, figures 2 and 3 show the impact of start-up on milk quality and the Transition Cow Index. We can see that, on average, milk quality improves right from the start. As for the Transition Cow Index, it follows production, falling slightly in the first year before rebounding in the second.

3. Conclusion

This preliminary analysis provides food for thought. Among other things, it confirms the wide disparity in construction costs in Quebec, and helps us better understand the causes.

We also notice that the transition to a new barn does not have a linear effect on production. It’s important to keep in mind that, in the year following start-up, productivity could decrease.

Further analyses will follow, enabling us to better understand the impact of building features on animal welfare, productivity, operating costs, and even gains in operating efficiency. The results will help farmers make informed choices when constructing a new building.