Maximize robotic milking efficiency to boost profitability

- March 9, 2020

- Le Producteur de Lait Québécois Magazine

On most dairy farms, increasing per-cow production improves profitability. On robotic farms, however, maximizing profit entails increasing the number of cows per robot as well as incorporating the notion of robotic milking efficiency.

Efficiency affects your bottom line

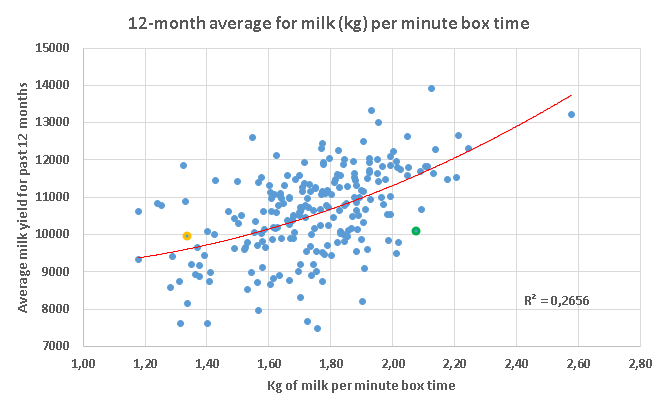

Robotic milking efficiency is measured in kg of milk per minute of time spent in the robot (box time). One might think that as a herd’s annual milk production increases, so does milking efficiency. However, as Graph 1 illustrates, this isn’t necessarily the case. In fact, the correlation between the 12-month average and the number of kg of milk per minute box time is only 26.6 per cent.

Graph 1. Variation in average milk yield for the past 12 months in relation to efficiency measured in kg of milk per minute box time*

*Data from 222 AMS Holstein herds, Lactanet, December 2019

A robot working at full capacity (assuming 10 per cent free time) has a potential milking time of 1,181 minutes per day. The yellow and green dots along the line for a 12-month average milk yield of 10,000 kg represent two different farms:

Yellow farm

1.33 kg of milk per minute box time x

1,181 minutes = 1,571 kg of milk

Green farm

2.07 kg of milk per minute box time x

1,181 minutes = 2,445 kg of milk

Both herds are producing an average of 10,000 kg of milk per cow per year, with milking robots working at full capacity, but the green farm is able to produce 874 kg more milk per robot. With an average feed profit margin of 0.5034 $/kg of milk, that represents a net profit of $440/day, or $160,600/year for the green farm (874 kg/day x $0.5034/kg for the Holstein breed based on the Lactanet 2020 Annual Herd Management Report). So robotic milking efficiency makes a big difference!

Four new parameters for greater efficiency

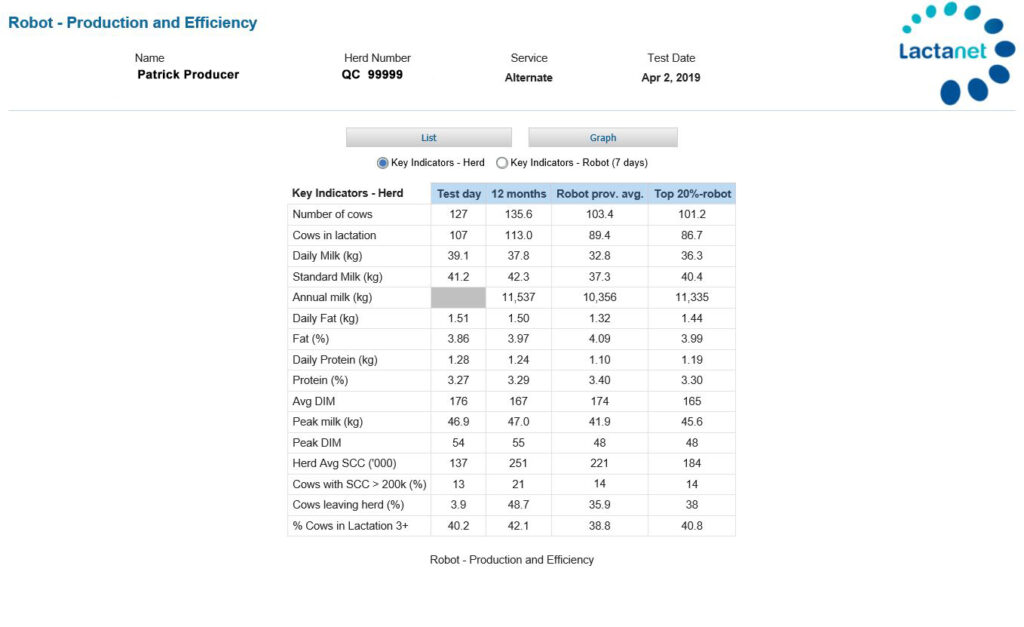

Measuring and monitoring milking efficiency is one of the main components of Lactanet’s new interactive report: Robot – Production and Efficiency. Milking time is evaluated at each test day by combining free time with a fixed factor to estimate time for cleaning, refusals and other periods during which the robot is unavailable for milking. These calculations make it possible to obtain comparable values among the different robotic milking systems:

- Average milking time measured in minutes

- Milking efficiency measured in kg of milk per minute in the robot (box time)

Projections based on actual results are also provided : - Maximum achievable milk yield per robot (in kg ) when the robot is at full capacity

- Maximum achievable fat yield per robot (in kg) when the robot is at full capacity

What’s the maximum yield target for each robot?

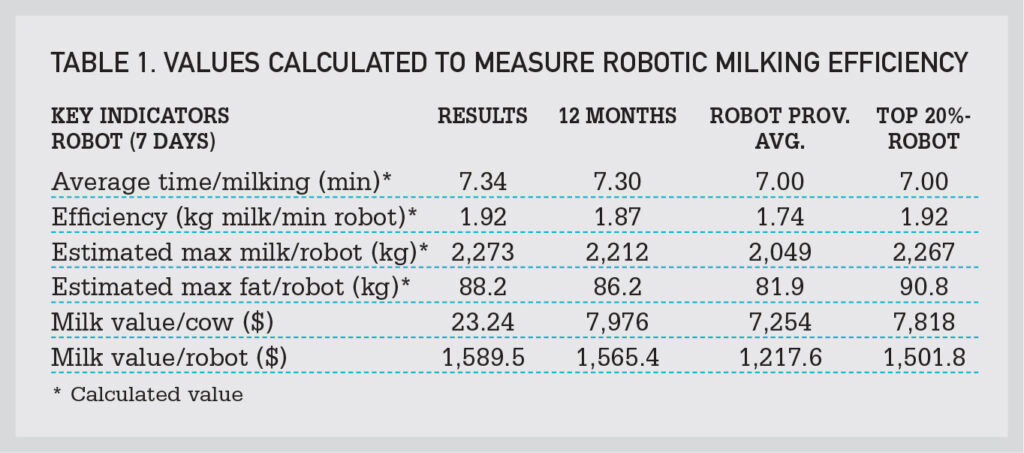

Table 1 presents test day results as well as the 12-month rolling average for the four key indicators listed in the first column. Maximum achievable yield (estimated maximum milk/robot) is calculated assuming 10 per cent free time. The actual efficiency value can be used to project into the future. Since improving efficiency is an ongoing process, you can start work immediately if the projected maximum doesn’t meet your expectations.

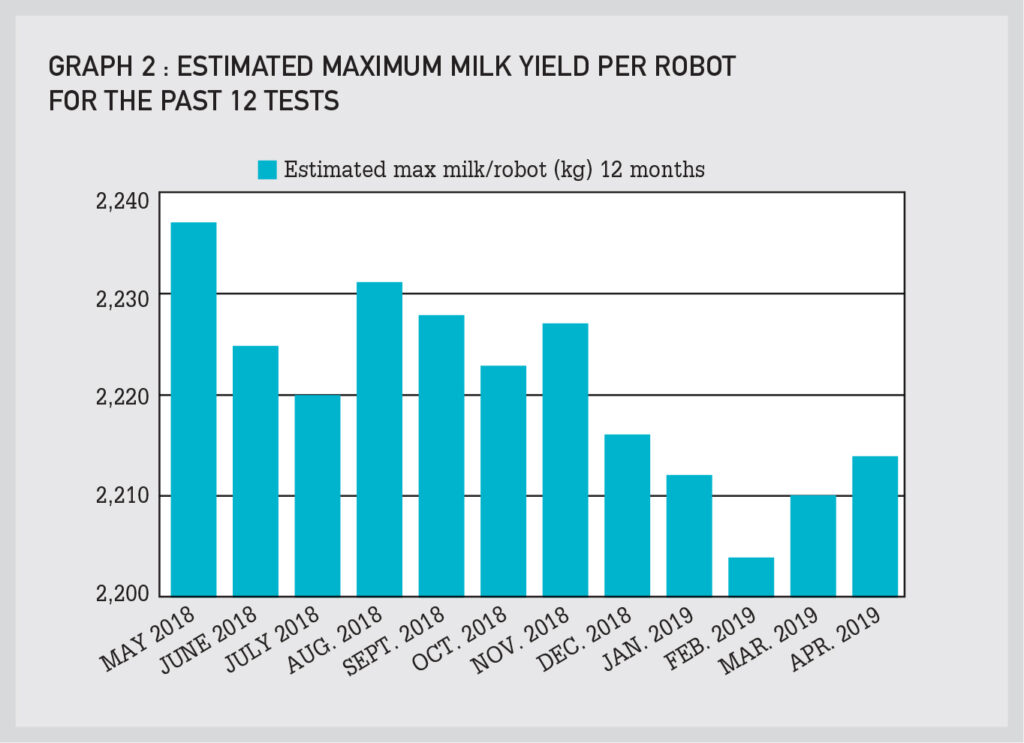

The graphs in the report (see an example in Graph 2.) show the evolution of this maximum value over the past 12 tests. The value is calculated from the 12-month rolling average to limit the effect of test-to-test variations and provide the best approximation of the future.

What affects efficiency in a robotic milking system?

Selecting top performing animals certainly contributes to improving robotic milking efficiency, but management factors also play a part.

Incomplete milkings

Incomplete and failed milkings probably have the greatest impact on efficiency. When they begin to increase, the free time decreases, and therefore so does the efficiency. This factor should be prioritized.

Preparation time

Both the robot (equipment failure, dirty camera lens, etc.) and the cows (poor udder conformation, bad temperament, long hair, etc.) influence preparation time (teat cleaning, teat cup attachment, etc.), which is included in milking time. Maintaining robots as recommended and keeping hair short on the mammary gland will save time.

Cows at the end of lactation

Late-lactation cows can be a source of inefficiency, as the udder at this stage contains less milk and teats are closer together. This complicates teat cup attachment and increases milking failures. Consider dry-off for cows producing less than 15 kg of milk/day.

A new type of interactive report to view your data

The traditional pdf report is now replaced with this dynamic data file, which allows you to view your data by clicking between two tables and eight graphs that will help you evaluate milking efficiency on your farm.

Benchmark your operation against the top robotic farms

The new report also includes the long-awaited provincial average by breed, based on the main breed of your herd, for the key robotic indicators. An additional column presents the average for the top 20 per cent of farms, ranked according to fat yield per robot. (Table 2)

Which factors influence robot efficiency on your farm? Call on a Lactanet advisor specialized in robotic milking for support in achieving your milking efficiency goals