Milking Robots, Where Efficiency meets Profitability

- April 25, 2022

- Le Producteur de Lait Québécois Magazine

When a dairy farm’s objective is to maximize milk production in the bulk tank, the calculation is simple: multiply the average production by the number of cows in milk. With robot milking systems, however, the robots operate continuously.

This means that, to maximize production, the cows must have additional aptitudes. Not only do they have to be good producers, but they also need to be more efficient in order to maximize the 1,180 minutes of milking that are available every day; this is approximately the time available for a robot that has 10% free time after considering wash time and other non available time.

To sum it up, milking robot efficiency is the number of kilos of milk per minute in the robot. Efficiency takes into account the period of time that the cow spends in the robot during two phases: the preparation and the milking phase. For a cow to be efficient she must, therefore, have a good temperament, good mammary gland conformation and an above average milking speed. This is the ideal cow for robot milking.

Does Productivity = Efficiency?

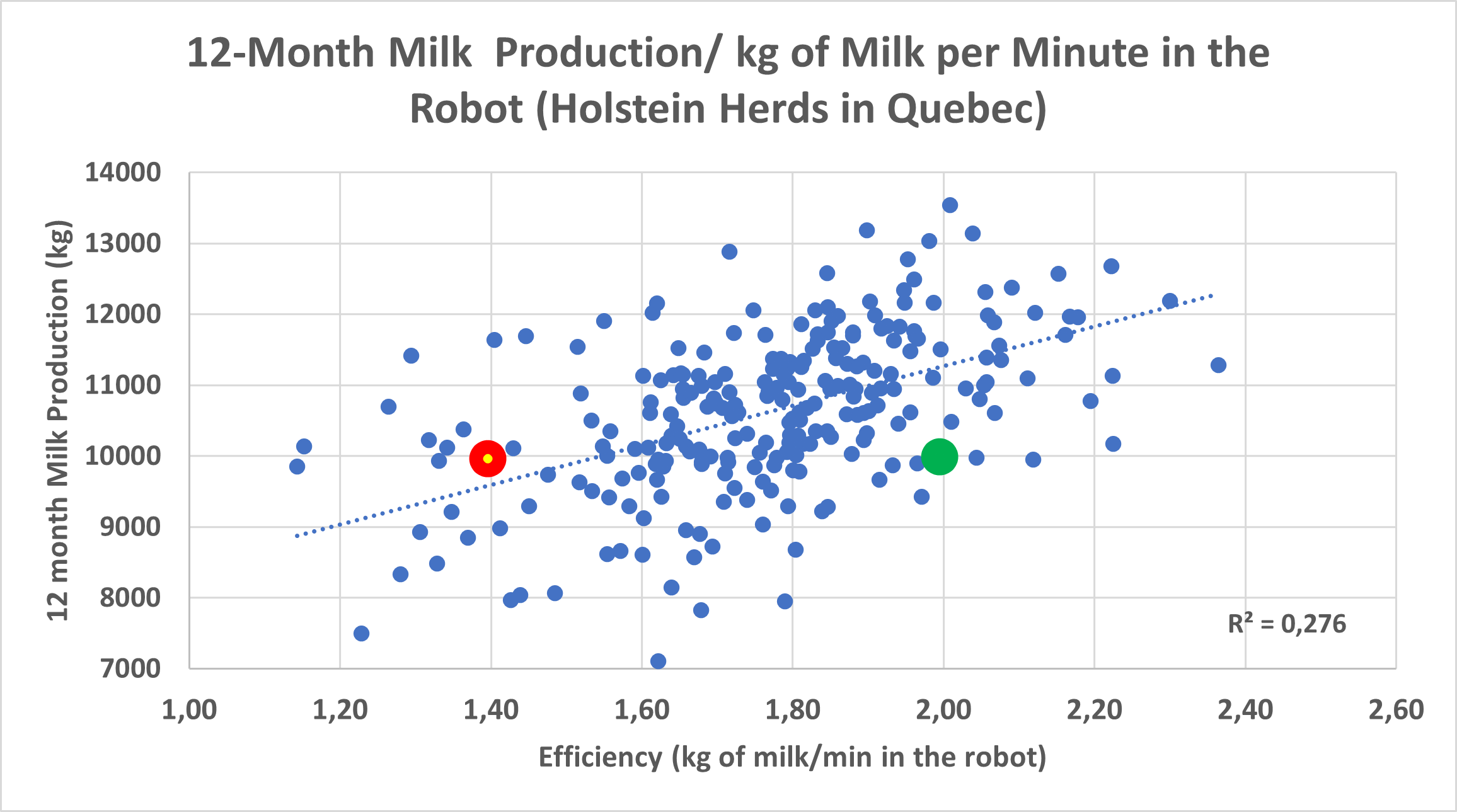

We often think that the higher the cow’s productivity, the more efficient the animal must be. This is the question that we looked at in 264 Quebec Holstein herds that subscribed to milk recording in March 2021. This can be true, but it is not necessarily always the case. The correlation is relatively low at the herd level [see Graph 1] and practically non-existent when looking at individual cows.

As you can see, there is significant variation among herds. We used the average of the last 12 months for both efficiency and production. In order to illustrate the impact of the variation more clearly in efficiency on productivity, a red and a green dot were added to the graph.

These points represent 2 farms that both have the same production average of 10,000 kg. The red farm has an efficiency of 1.40 kg of milk per minute in the robot, whereas the green farm has an efficiency of 2.0 kg per minute in the robot.

Let’s look at each farm’s potential productivity when the robots are full and there are 1,180 minutes available for milking:

Red Farm:1.40 kg/minute x 1,180 milking minutes

= 1,650 kg of milk

Green Farm: 2.00 kg /minute x 1,180 milking minutes

= 2,360 kg of milk

Evaluate the Herd as a Whole

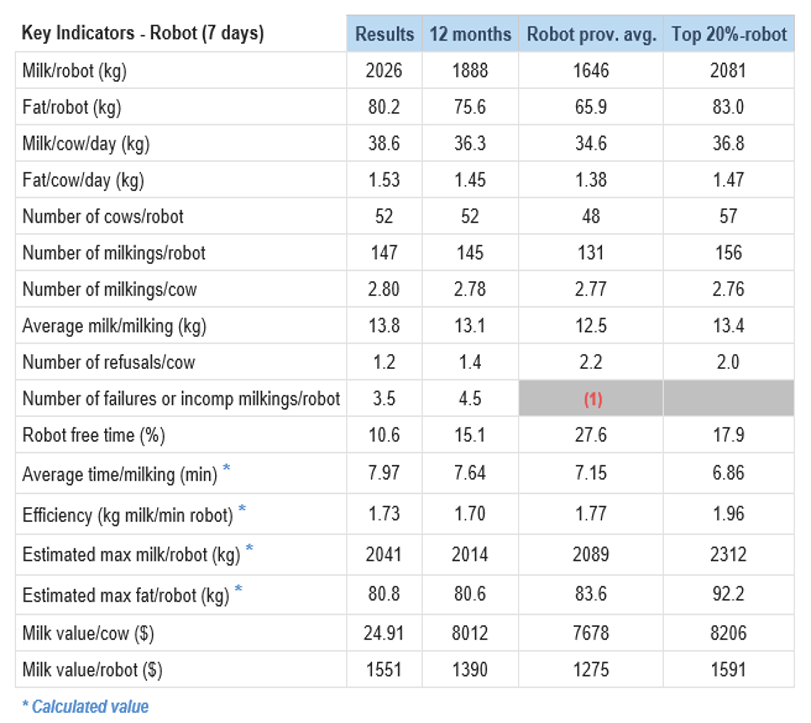

Since March 2020, the Lactanet robot report has provided four new calculated values that can help give you an idea of how your herd is doing. These new values make it possible for producers to compare with their herd’s 12-month average, the provincial average, and the top 20% of their breed.

In the example below [Table 1], the herd has good productivity per cow and a robot that is close to maximum capacity. Even though their production per cow is very good, the efficiency is below the provincial average. The two lines project the permitted production of milk and fat when the robot is at 10% free time. For this producer, we can conclude that the robot is full with only 52 cows using the robot.

The question that arises is: which cows are penalizing them the most ?

Co-creation Project with Eleven Producers

Lactanet is working on a project to identify the least efficient cows in the herd. In order to validate the direction of the project, eleven producers with DeLaval and Lely robots shared their evaluation of their current situation and what they need:

- Classifying cows by efficiency is not easy and is a long and tedious process;

- The methodology is not standard according to the manufacturers;

- The tool has to gather all of the data in one place;

- Must have an efficiency index expressed in $$$;

The data from five herds with Lely robots has been uploaded on a daily basis. This data is being used to develop a model for a tool that will try to rank cows according to efficiency.

Which cows are the least efficient?

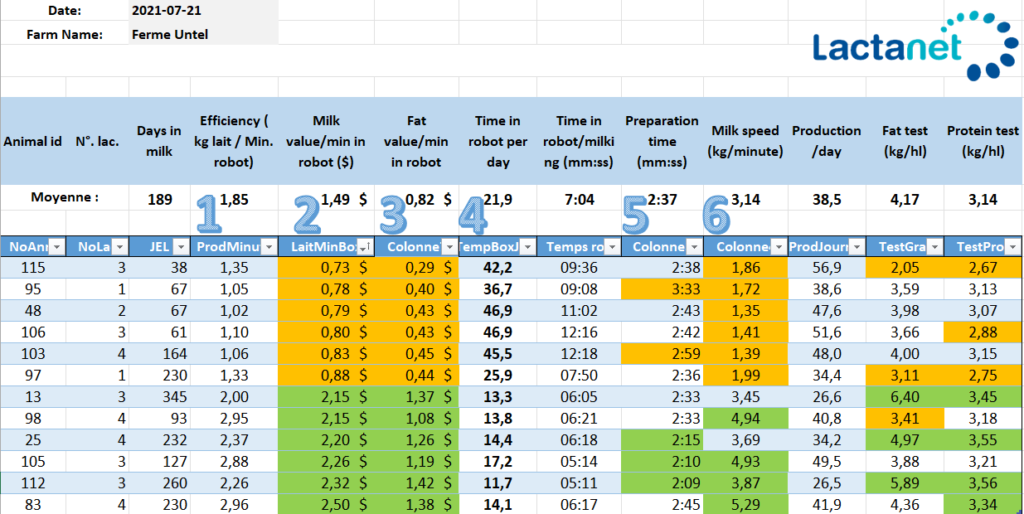

The ultimate objective of the project is to provide a list that ranks all of the cows in the herd to see which are impeding the herd efficiency and which are the best in the herd. The 96-hour ICAR standard is being used for the average calculation range.

For the purposes of this article, several columns in table 2 have been hidden. The orange cells indicate that the value for this cow is below 80% of the herd average and the green cells indicate that the value for this cow is above 120% of the herd average. The ranking is based on the milk value/minute in the robot. In this article, we can see the 6 cows with the worst and best performance according to this value.

Table 2. Example of Cow Ranking Based on Milk per Minute in the Robot.

The main details are listed below:

1: Efficiency in kg of milk/minute in the robot. It is also possible to make the same calculation based on successful milkings, in order to highlight the cows that have had milking failures.

2: Milk value/minute in the robot. Cell 1 is multiplied by the milk components and price of each of the milk components.

3: Many producers wanted to have a ranking based on fat. This is the same calculation as the previous one, but using the kg fat/minute, the fat test and the price of fat per kilo.

4: Time spent in the robot per day. Allows you to see that although some cows are very productive, they use far too much of the robot’s time.

5 and 6: The preparation time and milking speed based on a 96-hour average. These are two important elements that can explain why the cow has a low rating. The preparation time is primarily connected to a cow’s temperament and udder confirmation whereas milking speed is more related to a cow’s genetic potential. In the case of cow number 95, the long preparation time and a slow milking speed explains her ranking. However, in the case of cow number 48, only her milking speed is a problem.

What should you remember about this new ranking?

When you look at individual cows, you can see that it is very variable. There are some very productive cows that are not very efficient, and others that are much more so. Take for example a cow in [Table 2] to better understand the impact of efficiency. Cow number 48 produces 48 kg of milk and uses the robot for 47 minutes per day. If all of the cows were like her, the robot would be full with only 25 cows and the production per robot would be below 1,200 kg. The herd average is 21.9 minutes per cow in the robot per day and the average production is 38.5 kg of milk. If this cow was sold, it would free up 47 minutes that could be filled by animals that are closer to the herd average, 2.15 cows x 38.5 kg of milk, therefore a total of 83 kg of milk, amounting to gains of 36 kg of milk in the same number of minutes. Even better if you consider the best cows; cow number 105 gives 49.5 kg of milk in 17.2 minutes!

Lactanet is currently working on the automation of this process in order to provide a tool for our clients that will allow them to rank the cows according to their efficiency. At a glance, you will be able to see whether milking speed, preparation time, or both, are connected to an animal’s lack of performance. Making productivity and profitability rhyme has never been so fast and easy!