Portrait of Ferme Yves R. Couture: The Chop that Can Make All the Difference

- May 24, 2021

Since the fall of 2020, the components at Ferme Yves R. Couture have been slowly decreasing. With the help of PROFILab, we tested some feeding solutions, but nothing was conclusive. Some time later, we began to question the forages in the PMR. We compared the old rations and made some observations. Let’s find out more about this story and its happy ending.

Owners: Gilles Couture and Annie Benjamin

Succession: Julien and Lili-Rose Couture

Location: Ham-Sud

Herd Composition: 55 Holstein cows

Housing: Freestall, on compost, robot milking

Feeding: PMR + robot feeds

Over the last few years, the owners of Ferme Yves R. Couture changed their production style. In 2018, they decided to make the move to robot milking. Their goal? Improved comfort for their animals as their old barn was at a turning point: to stop or push on?

The initial plan was to keep the same feeding as in the past, with round bales and grain. They began their robot feeding with two types of feed, fed in the robot, with the possibility for a third. Not long after the transfer, the third feed was added to the robot. Corn silage was also incorporated shortly before the transfer to robot milking. With only one 18 x 70 structure to store their corn silage, the quantities in the ration could not be too plentiful. They limited corn silage to 8 kg in the winter and 15-20 kg in the summer (storage structure and good feed out in the summer). This allowed them to optimize the opportunity to keep good quality silage in the summer, while having enough tonnage to feed the herd for the whole year. The ration was made up of grass silage from round bales, corn, grain (barley), soybean meal and minerals. Corn grain is added when necessary.

So, what happened on the farm?

In the fall of 2020, the farm began to see a drop in their milk components. This happened at a time of year when things should be picking up with the summer having ended. Surprisingly, the components had actually gone up between July and October. Similar variations had been seen before at abnormal times.

Possible causes such as sorting had already been examined, but we did not suspect that the situation would be so problematic…

Demonstrating Sorting with a TMR

One sign of sorting is that the cows make circles in their TMR or PMR. They try to eat the finer grain particles before eating the silage. They don’t know that doing so can bring about significant repercussions on their rumen health.

The first step is to repeat Penn State testing on the round bales that are being chopped in the mixer. After all, a mixer is meant to mix and not to chop. There are risk factors that need to be taken into consideration when chopping silage in a mixer:

- When the mixer is empty, check the condition of the blades. If you can easily pass baling twine over the blades without them being cut, it is time to sharpen the mixer blades. Ideally, use forages that have already undergone a « full rotocut » to reduce chopping time and your electricity bill;

- Validate the actual mixing time required to chop your forages. The difference between the estimated time and the actual time can be surprising.

Back to Ferme Yves R. Couture

When collecting data on the farm, the observed mixing time for round bales was 26 minutes. Theoretically, when using Penn State, we like to have less fiber on the first sieve (10 to 20%) than on the second, because this fiber will be sorted by the cows. The second sieve, which has our most important fiber, should contain (by weight) the most silage particles (45% to 75%) while the third sieve should be between 10% and 20% and the fourth less than 20%, as these are the particles that line the rumen without making it work.

The results of the four Penn State sieves for the farm after 26 minutes of mixing are provided below:

Remaining Particles (% of Total) |

| 73 15 2 11 |

I had suspected that there was some sorting going on, but upon seeing the results, I was astonished. We had done tests in the past and it had definitely not been this problematic.

The weight and dry matter of the round bales have an impact on the ease of chopping forage in a mixer. A single dry round bale chopped in a mixer with blades that are not properly sharpened will have pretty disappointing results, even after a longer mixing time. A dry round bale, when placed in the mixer first with a fermented round bale on top will put some weight on the lightest of the two, which will put pressure on the knives. In the event that the round bales are too dry, the first step is to ensure that the blades have been properly sharpened. Then, instead of adding water at the end of mixing, add it at the beginning to add more weight as soon as you start mixing. This strategy will make the forage less light. And that is what we did.

Next, we did several tests at 26, 30, 35, 40, 45 and 51 minutes of mixing. These are the results from 45 (left) and 51 minutes (right) of mixing:

| Remaining Particles (% of Total) |

| 45 34 3 19 |

| Remaining Particles (% of Total) |

| 32 27 3 38 |

After analyzing our results, we decided to go with 45 minutes of mixing, given that we were losing too much fiber on the second sieve when increasing to 51 minutes. The results from the final PMR were much better than what we had started with. We also mixed in the corn silage in at the end so that it would not get chopped more than it already was. Finally, we noted that it was important to use the appropriate mixing times on the round bales.

**Do not forget that round bales will continue to chop when grains and corn silage are added to the mix…

Important Factors to Validate with TMR/PMR

Penn State tests, manure screens and grain screens have always been important, but are even more so now that producers are dealing with feed prices that are constantly increasing. Each test can help improve results:

- Silage chop length: aim for ½ inch for hay silage and ¾ inch for corn silage;

- Particle size of the final TMR or PMR: do we break down our silages more than necessary vs. their original condition?

- Mixing time

- Moisture in the ration

- Uniformity of a ration with grains and minerals

- Sorting: grain size distribution (granulometry)

- Blade condition: Necessity of using the blades in certain cases that don’t have round bales or square bales to chop

All is Well that Ends Well

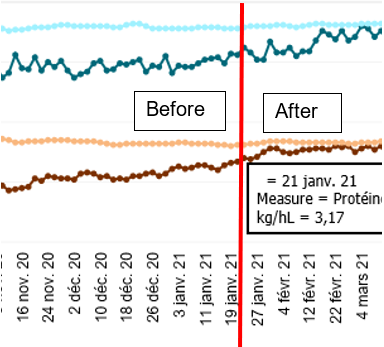

Since January, the cows at Ferme Yves R. Couture once again have more consistency in their components. The fat is more stable, mostly between 4.20 and 4.25 kg/hl, versus 3.95 to 4.05 kg/hl before our tests. The protein has increased to between 3.20 and 3.30 kg/hl versus 3.10 to 3.15 kg/hl before the feeding adjustments were made. Their milk is equal to or superior to what is was before.

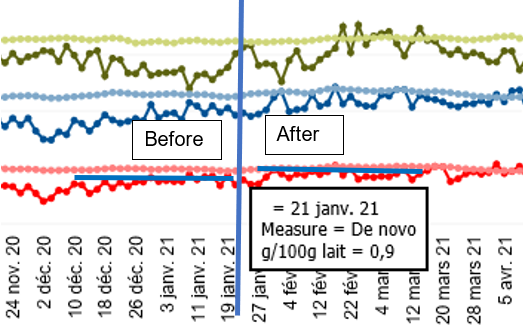

Since January 21st, our PROFILab indicators now show that rumen health has improved (de novo fatty acids) and the improved components are the result of this.

PROFILab: Preformed, Mixed and de novo

With the current controversy around palmitic fats, this type of situation puts a smile on the producers’ faces, as with the same feed inputs, a little more electricity and the same milk, they have more money in their pockets.

This project is funded through the Innov’Action agri-food program under the Canadian Agricultural Partnership, as part of an agreement between the governments of Canada and Quebec.