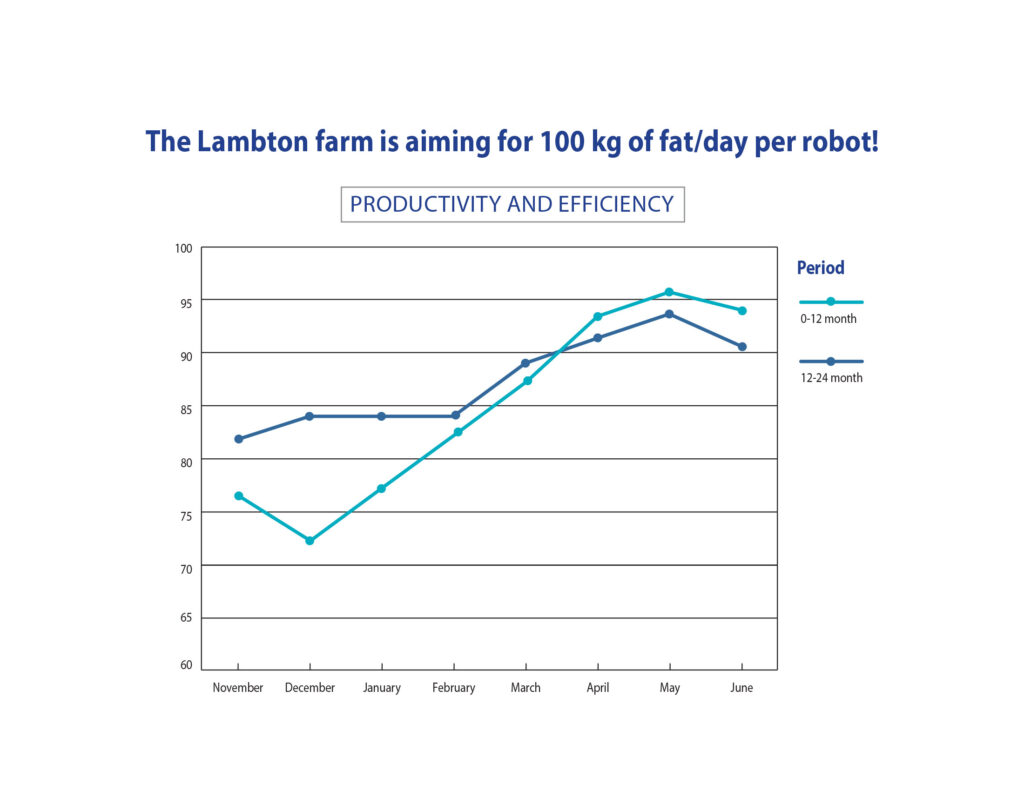

The Lambton farm is aiming for 100 kg of fat/day per robot!

- October 26, 2023

Ferme Lambton, owned by Sylvain, Marie-Ange and Maurice Richard, invested in a new barn with two robots 11 years ago. Sylvain’s daughter Marie-Ange has been involved full-time with the farm for 6 years. One of her responsibilities is herd management, with her brother Maurice in charge of feeding rations and robotic maintenance.

They focused on the efficiency of robotic milking: “When I arrived, we had 90 cows producing 130 kg G/day. Our quota is now 175 kg/day with 120 cows in lactation. We’ve gone from 65 kg/day to 87 kg/day per robot”. She says she is “growing from within” by increasing quotas without buying additional equipment, aiming for a quota of 200 kg G/day.

To achieve its objective, she is focusing on two aspects:

1. Robotic milking efficiency:

To improve efficiency, Marie-Ange is putting into practice the concepts she learned from Lactanet’s robotics resources: “I’m collaborating on the development of a new cow efficiency report for robotic milking. This report makes it easier to identify and select the least efficient cows. I’ve taken action by selling the less efficient cows and buying new ones. My goal is to reach 2.1 kg of milk/minute with the robots.” This goal compares favourably with the provincial average for Holstein herds, which is 1.83 kg milk/min, with the best 20% achieving 2.05 kg milk/min on the robot.

Having assimilated the robot efficiency parameters discussed at Lactanet robotics workshops, Marie-Ange easily lists the robot data that contributes to milking efficiency:

- Fewer milking refusals;

- Reduced teat hook-up time;

- A reduction in milking failures;

- Improved milking speed.

2. Improving the fat percentage of the herd.

Ms. Richard believes it’s quicker and easier to improve fat/robot by increasing fat content than by improving kg of milk per cow. Over the past year, the fat content in the tank of her Holsteins has ranged from 4.15 kg/hl to 4.37 kg/hl. The ration is balanced according to the recommendations of her Lactanet advisor Daniel Tessier. Daniel helps him choose the ingredients that maximize the margin over feed costs. Teaming up with Lactanet technician Réjean Fontaine, they provide her with useful tools and reports to leave nothing to chance, such as PROFILab, Transition Management Index, Robotic milking, KetoLab and Milk Urea. “In the end, the advice and tools help us to manage the herd so that we have more left in our pockets,” says Marie-Ange.

She sets high genetic selection thresholds to improve fat production (kg and %) and the important criteria related to robotic milking: milking speed and teat placement. She uses sexed semen for 90% of her heifers, and 60% of her cows receive semen from beef bulls. “I make my choice of semen to meet the replacement needs established with the help of my advisor at 4 heifers per month.”

Graph 1 shows that milk recording from April to June 2023 displays more than 90 kg fat/day produced per robot, while the Quebec average for robotic farms is 69.1 kg fat/day.

The time required to reach 200 kg F/day will depend on the availability of quotas. The managers feel well supported by Lactanet in their efforts to produce more without making major investments. They are counting on sustained herd management and the selection of efficient cows on the robot to achieve this. “We work with live animals, there’s nothing perfect, there’s always something to adjust to achieve our goals,” says Marie-Ange.